Ampreg™

Low toxicity wet laminating systems

for high-performance composites

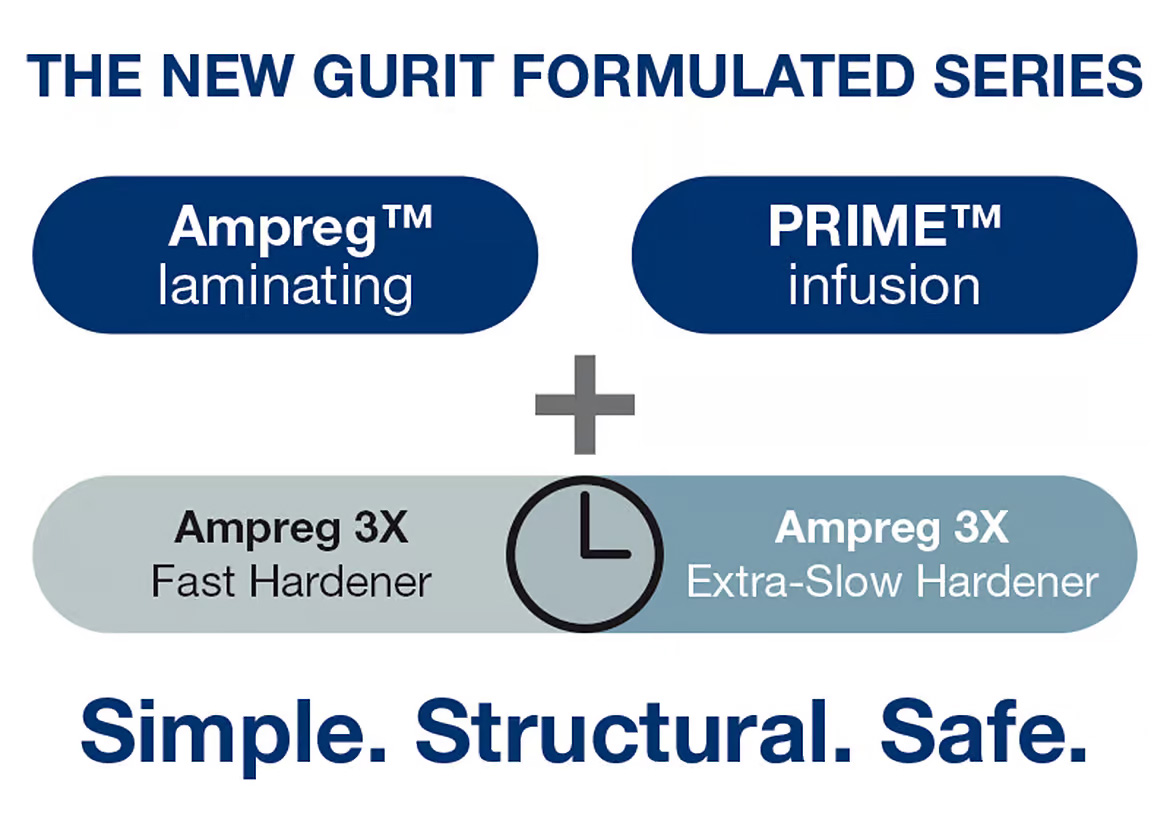

Combining market-leading performance with improved health and safety, the Ampreg 3X Series are the latest generation of Gurit’s wet laminating technology. Engineered for a wide range of applications, from high-performance yachts and wind turbine blades to industrial composite structures, Ampreg offers excellent mechanical properties, reliable cure behavior and enhanced environmental credentials.

Low Toxicity, High Performance Epoxy Laminating Systems For Marine, Wind, And Industrial Applications

Why choose Ampreg

The Ampreg range has been designed to simplify composite manufacture while enhancing safety and performance. Developed with Gurit’s award-winning low-toxicity 3X hardeners, Ampreg resins deliver excellent laminate mechanical properties and are free from CMRs (carcinogens, mutagens, and reprotoxins) and SVHCs (substances of very high concern).

Ampreg is Ideal for

Engineered for versatility and ease of use, Ampreg systems deliver outstanding laminate quality across a range of hand-layup and vacuum-assisted processes. Designed for ambient or elevated-temperature cure, Ampreg provides excellent fiber wet-out, predictable cure progression, and durable mechanical performance.

Laminating glass, carbon, or aramid fibers in marine, wind energy, and industrial components

Structural and secondary composite parts

Hand lay-up and vacuum bag laminating applications

Large structures requiring extended working time

Certified applications requiring Lloyd’s Register or DNV approval

Product selector

Laminating Systems

Ampreg 30 Resin

Low viscosity, ambient cure, DNV Certified

LRT

Ampreg 31 Resin

Viscosity optimized for wet-out and drainage resistance, DNV Certified

LRT

Ampreg 32 Resin

CMR Free, Low viscosity, ambient cure

LRT

CMR free

Ampreg 33 Resin

CMR Free, Viscosity optimized for wet-out and drainage resistance

LRT

CMR free

Ampreg 36 Resin

Improved impregnation, improved mechanical property generation, High flexural properties

LRT

Speciality Systems

Ampreg 21FR Resin

Fire retardant, Indicative FST performance (FAR Part 25) (60s flame applied)

FST

Ampreg 3X AP Resin

Improves vinylester/epoxy adhesion & to enable use of polyester gelcoats

Promotes Bonding

Ampreg 3X F230-2 Resin

Foaming epoxy, 150– 300kg/m3

Expanding

Ampreg TP Resin

Thixotropic additive for resin drainage control for Ampreg 30, 31 and 36

Higher Viscosity

Ampreg 32/33 TP Resin

CMR Free, Thixotropic pregel for Ampreg 32/33

CMR free

Light Reflective Technology As Standard

Ampreg 30 is available with LRT (Light Reflective Technology) as standard, which serves as a risk monitoring feature for the user and enables inspection of contamination by means of UV light. To learn more about Gurit® LRT technology, please refer to the respective data sheet.

Ampreg is the ultimate solution for those looking for a safe, reliable, and high-performance epoxy laminating system.

Discover how Ampreg can support your next project or inquire about becoming a distributor.

The PrimE and Ampreg ranges now contain Biomaterials as standard, with the ability to reduce CO2 by up-to 32% over non-bio options.

- No compromise on performance

- No price premium

- Reduced CO₂ footprint as standard

Download related Documents

Get in touch with us to learn more about Gurit and how our solutions can work for you.

© Gurit Services AG, Zurich (CH)