Solutions

& Services

Engineered Performance from Concept to Production

Gurit combines decades of composite expertise with engineering excellence, digital optimization tools, and a worldwide service network. From structural engineering and manufacturing process development to precision kitting and digital core optimization, our solutions help customers build lighter, stronger, and more efficient composite structures.

We support the full product lifecycle across the wind energy, marine, and industrial sectors — delivering reliable performance and manufacturing efficiency at every stage.

Integrated Expertise, Digital Tools, And Global Support For Advanced Composite Manufacturing

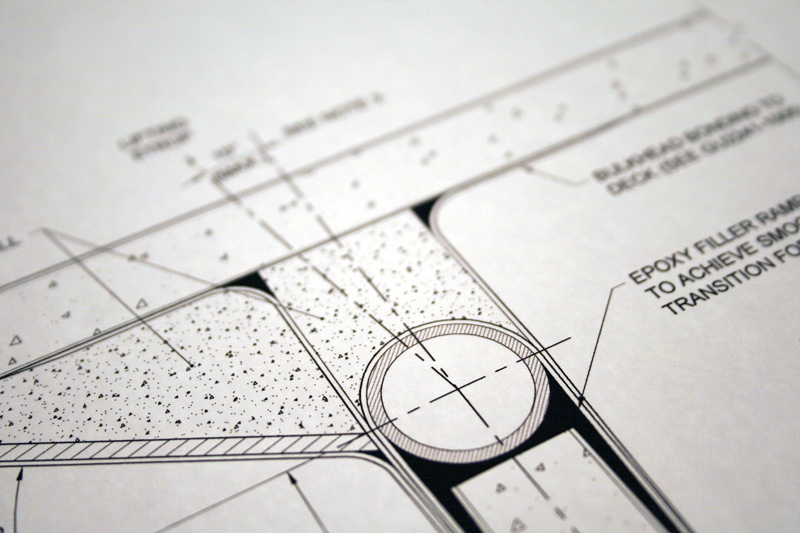

Structural Engineering

Your partner in innovation that delivers stronger, lighter, and more efficient structures

Gurit engineering provides deep composite expertise across structural design and laminate specification, FEA optimization, mechanical testing, regulatory compliance and onsite support.

Our team helps customers:

- Reduce weight and increase structural stiffness

- Improve fatigue life and long-term durability

- Optimize laminate schedules and material selection

- Accelerate development and approval

- Optimize materials and manufacturing processes

- Transition to composites from traditional materials

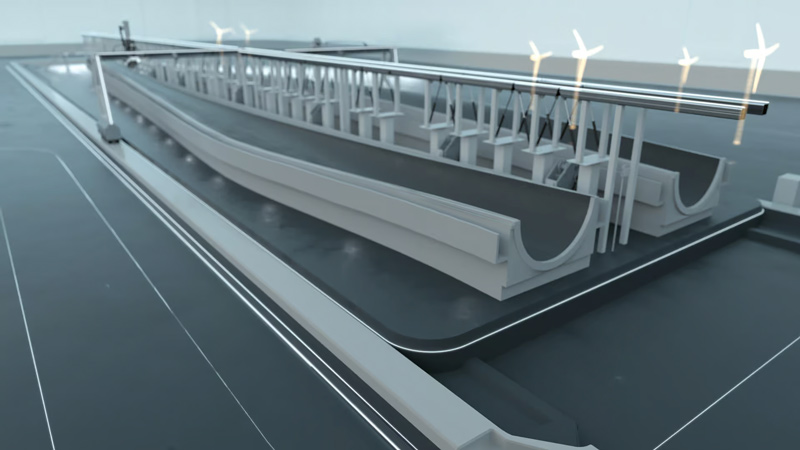

Manufacturing Solutions

Precision composite molds and plugs for lightweight, durable structures across industries

Specializing in wind turbine blade molds and automation, the team also supports emerging sectors like wind-assisted ship propulsion with advanced engineering expertise.

Our services include:

- Engineering services

- Large scale plugs and molds

- Manufacturing automation for wind blades

- Manufacturing intelligence

Core Services

Precision, efficiency, and global capability for core materials

Precision Core Kitting

Precision-cut core kits streamline assembly, reduce waste, and ensure reliable quality worldwide.

Benefits include:

- Accurate fit and faster layup

- Optimized nesting and reduced scrap

- Improved resin uptake control

- Global kit production near composite manufacturing hubs

- Consistent quality and repeatability

CNC Processing and Finishing

Gurit provides a full range of finishing options for PET, Corecell, Balsaflex, and PVC cores.

Options include:

- CNC machining

- Grooving, perforations, scoring, and pinholes

- Thermoforming and pre-shaping

- Flexible and rigid formats

- Film, scrim, and surface treatments

These finishing options ensure reliable performance in infusion, prepreg, and hand-layup processes.

Opticore – Optimized Core Kitting For Wind

Parametric design for lighter, more efficient wind structures

OptiCore is Gurit’s next-generation parametric design platform developed specifically for wind blade engineered core kits.

It enables manufacturers to:

- Minimize resin uptake and reduce blade weight

- Achieve faster design iterations to shorten development cycles

- Improve blade performance

- Be assured of a precision-fit

- Consistency across global production sites

Our focus on precision and repeatability reduces complexity, supports lean manufacturing, and delivers lasting reliability in the most demanding environments.

OptiKit – Digital Core & Kit Optimization for Marine

Engineered kitting for optimization

OptiKit brings powerful digital optimization to marine and industrial applications. Drawing on the same digital design intelligence that underpins our wind industry solutions, it delivers optimized and accurate production-ready core kits for a full range of composite sandwich structures.

OptiKit helps manufacturers:

- Optimize core geometry using parametric design

- Reduce resin usage and overall structural weight

- Improve component performance

- Ensure consistent kit quality across programs and sites

- Accelerate time-to-first-part and standardize production

Fulfilment Center Support

Local availability and responsive service worldwide.

Gurit’s fulfilment centers provide localized support for composite manufacturers, offering:

- Regional stock and rapid delivery

- Customer-specific inventory programs

- Technical support and troubleshooting

- Aligned logistics for OEM and Tier 1 production schedules

This ensures stable supply, minimized downtime, and efficient manufacturing flow.

Innovation & Open-Source Development

The Gurit98m – accelerating composite engineering and innovation.

The Gurit98m offshore wind turbine blade model is an open-source platform designed to support industry-wide innovation. It enables research into structural optimization, recyclable materials, manufacturing processes, and next-generation offshore blade design.

Partner with Gurit

From digital optimization and structural engineering to manufacturing solutions and global kitting, Gurit provides the expertise and services needed to design and build composite structures with confidence.

Get in touch with us to learn more about Gurit and how our solutions can work for you.

© Gurit Services AG, Zurich (CH)